Planning, Execution and Supply of high efficient and low emissioning Combined Heat and Power Stations

Highly flexible and environmentally protecting Power Stations and Residue Waste to Energy Plants

Tailor-made and competent Consulting, Engineering, Execution and Commissioning

HUTTER FREI POWER develops, plans and delivers high-grade combined heat and power (CHP) stations, rotary kiln delacquering plants, thermal residue-to-energy plants and acts as General Planner for power stations and waste incineration CHP plants.

As Consulting and Planning Engineer we work for public institutions, industries and financial services provider. Our range of services in the consulting phase includes project development studies, pre-studies and feasibility studies as well as pre-engineering orders.

Our products distinguish themselves by innovative, high-grade, low-emissioning and high-efficient solutions, which we constantly further develop.

We develop optimised solutions tailored to meet the individual needs of customers and provide our services with the newest state of the art.

An additional customer benefit is our combined knowledge as Supplier and Consultant.

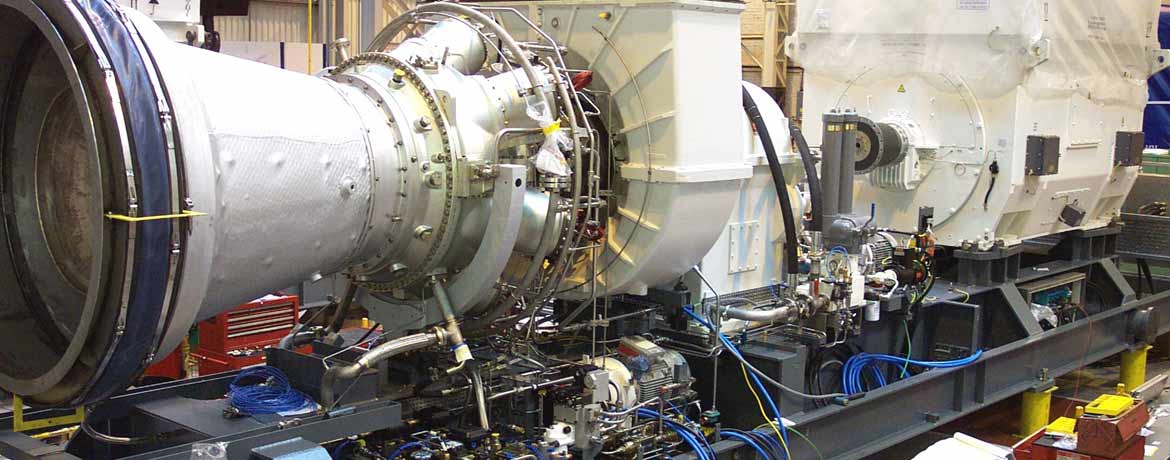

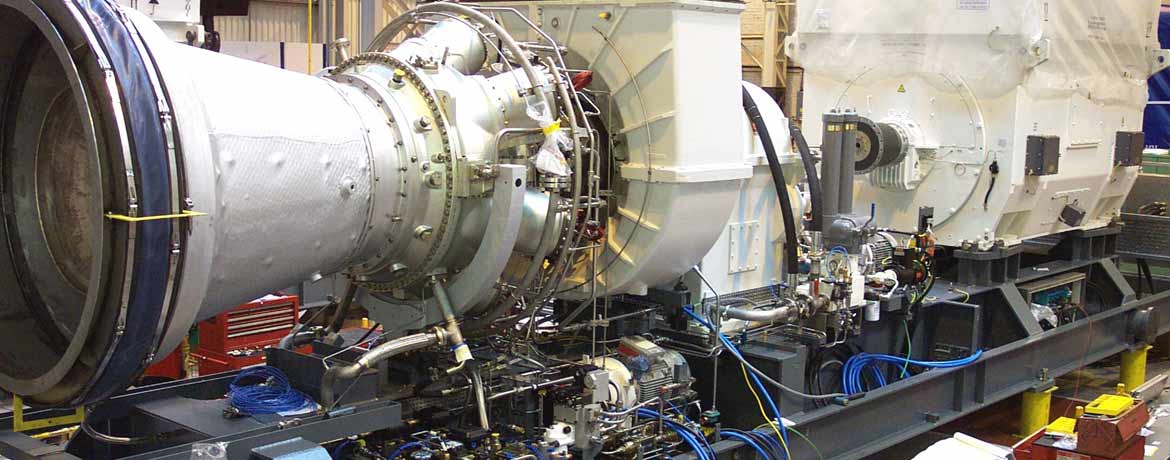

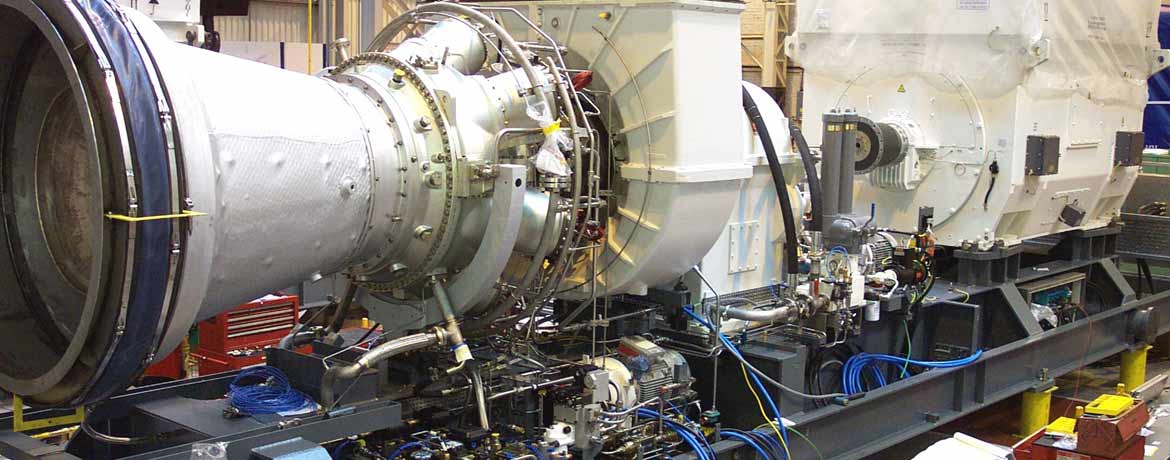

As one of the Pioneers we built 1989 the combined gas- and steam turbine CHP station SYSTEM HUTTER for the manufacturing industry. This CCGT CHP station SYSTEM HUTTER Varel 1 is still in operation today with its low-emissioning technology, the nominal efficiency of 93% and the high-grade quality.

The CCGT CHP station SYSTEM HUTTER with radiation-type steam generator has been developed by Mr. Friedrich Hutter for the simultaneous need of electricity and process steam and protected by patent.

The basis of this concept was offered by a research project of the German Ministry for Research and Technology for determining the CHP potential in industry and trade.

For the simultaneous need of electricity and hot water or district heating we developed a combined cycle GT CHP station with heat recovery boiler with low-emissioning firing at all part loads.

Moreover we are specialised in the thermal calculation and engineering of radiation-type steam generators and heat recovery boilers.

In 2016 we commissioned a pilot plant of a rotary kiln plan for delacquering of Used Beverage Cans (UBC). Until 2017 we have modified the delacquering plant based on the operating experiences and brought it to the highly reliable continuous operation.

Based on the operating experiences we have further developed the delacquering plant and supply rotary kiln plants for UBC- or aluminium recycling for energy savings and for minimisation of the material loss.

> Further information about CCGT CHP stations, power stations, thermal residue-to-energy plants and rotary kiln plants can be found here.

Our company acts as:

> Further information about our activities as Engineer and Supplier in the power station technology and the thermal recycling technology can be found here.

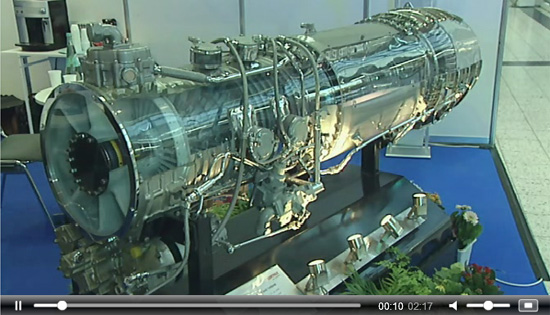

In the following video clip, we give an overview about the activities of HUTTER FREI POWER and about our combined cycle gas turbine CHP station SYSTEM HUTTER.

Furthermore executed CHP stations and an exhibition model of a cut-away gas turbine are shown.